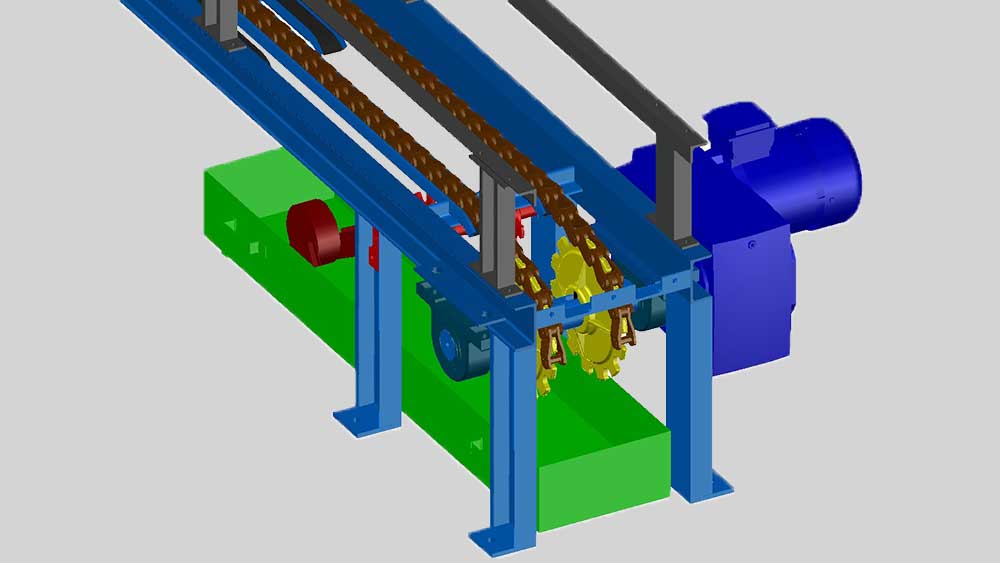

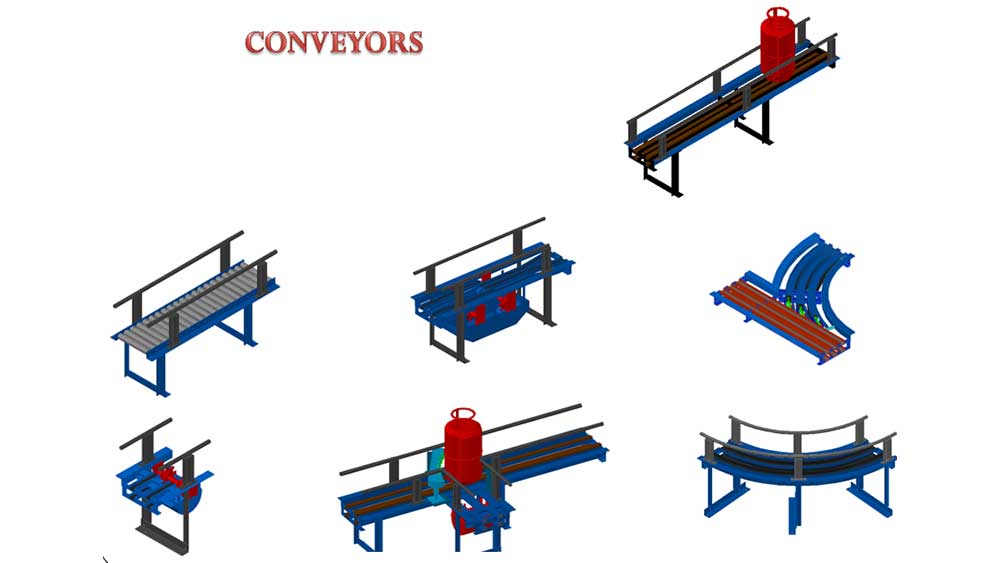

Chain Conveyors

Utilize a continuous chain to transport LPG cylinders through various stages of the bottling process. These systems are designed for heavy-duty applications and can handle long distances within the plant.

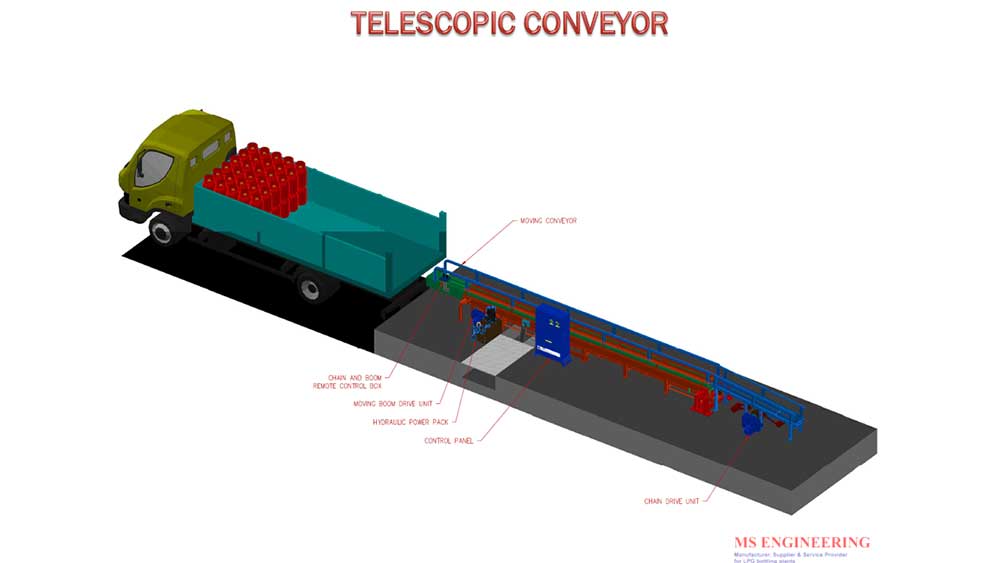

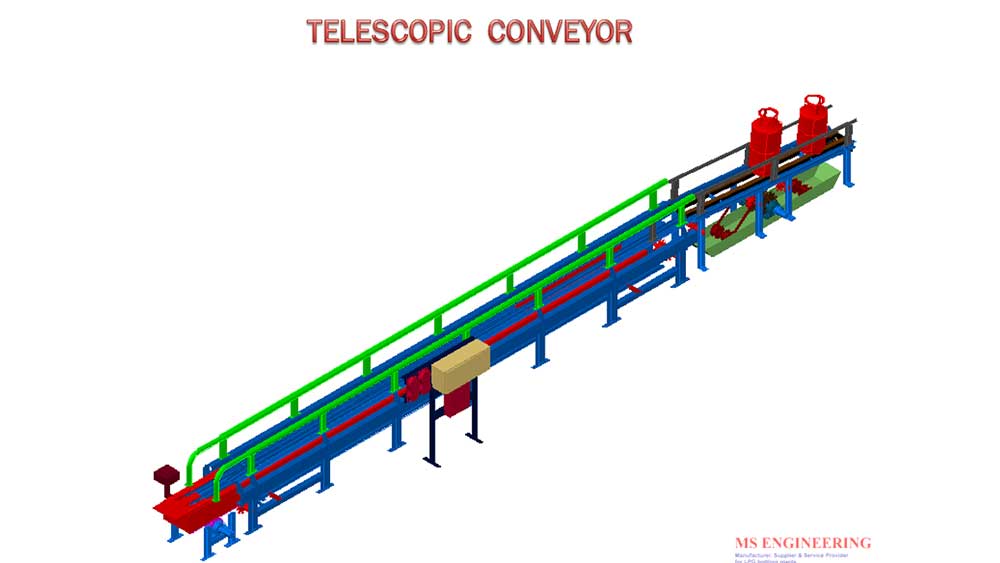

Telescopic Conveyors

Facilitate the loading and unloading of cylinders from trucks. These conveyors can extend and retract, allowing for flexible and efficient handling of cylinders at varying heights.

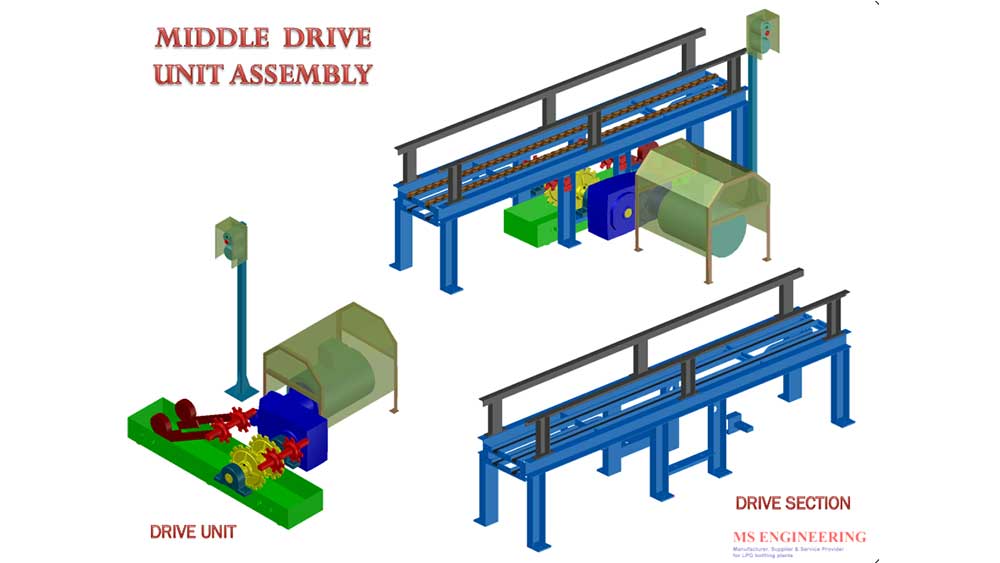

Drive Systems

Geared Motor Drives

Provide the necessary torque to move conveyor chains. These drives are selected based on the required pulling capacity and are crucial for ensuring smooth and continuous operation.

Flame Proof Motors

Essential in environments where flammable gases are present. These motors are designed to prevent ignition of the surrounding atmosphere, ensuring safe operation in LPG bottling plants.

Inline Water Test Bath

An Inline Water Test Bath is a critical component in LPG bottling plants, designed to detect leaks in filled cylinders by submerging them in water. This process ensures safety and compliance with industry standards

Key Features

- Leak Detection: Cylinders are passed through a water bath where any leaks are identified by observing bubbles.

- Integrated Conveyor System: Features guide rails and a chain conveyor for smooth cylinder movement through the bath.

- Safety Compliance: Helps meet regulatory standards by ensuring all cylinders are leak-free before distribution.

Galvanized Conveyor Systems

Our galvanized conveyor systems are engineered to provide robust and reliable transportation solutions for LPG cylinders. Key features include:

- Corrosion Resistance: Galvanized components ensure longevity and reliability, even in challenging environments.

- Modular Design: Flexible configurations to suit various plant layouts and operational needs.

- High Load Capacity: Designed to handle heavy-duty operations, ensuring continuous and efficient cylinder movement.

Spare Parts for Bottling Plants

We provide a comprehensive range of spare parts essential for the maintenance and smooth operation of LPG bottling plants.

- Our offerings include:

- Roller conveyors, conveyor rails & tracks, sprockets, shaft, pneumatic cylinders, pneumatic connectors, bearings, stoppers, ETC….